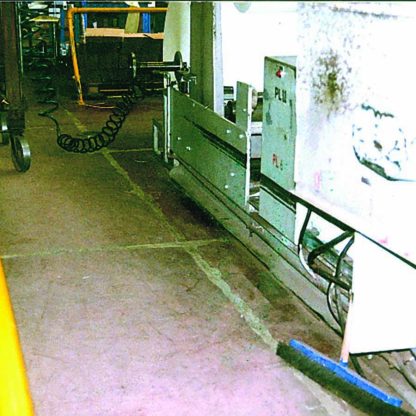

Jointex EP is an incredible expansion joint material that offers long term protection. One of the major issues with all expansion joint materials is that fact that they are soft and ‘squash’ when traversed by heavy weights, particularly those with small, hard wheels resulting in an extremely high point loading. As the joint squashes, the weight is transferred to the shoulders of the joint, the concrete then starts to crumble and this only increases the problem. As the concrete breaks up, so the jointing compound ‘falls out’ causing, quite probably, the very problem you have today.With its unique combination of strength, flexibility and incredible adhesion, Jointex EP is THE answer for the sealing and protection of concrete expansion and construction joints in areas of highly trafficked areas .

Use on:Concrete. For other substrates contact Polycote Experts

Use where:Internal/External

Type of job:Sealing concrete expansion and construction joints

Approximate coverage:5 kg unit – 45 Linear metres @ 10 x 10mm

Cure time:18-24 hours @ 20oC

Special features:High strength, extra flexibility – allows 10% joint movement, extra chemical resistance, incredible compressive strength

Pot life:40mins @ 20oC

Application temperature:5oC to 30oC

Depth of repair:10mm – 25mm

Fully cured strength:26N/mm2

Number of parts supplied:2

Priming required:No

Please consult the technical data sheet for full technical product data.

Preparation:Thorough substrate preparation is essential.

All joints must be clean, dry and free of dust, loose material or previous joint sealant. A gas torch may be used to help remove oil or moisture from the surface.If the edges have broken away – repair using Polycote Cretex® EP. Depending on the extent of the repair, the Cretex material may be supported using a thin polythene covered batten until firm. Alternatively, the more professional method is to totally fill the joint with Polycote Cretex EP and once cured, re-cut in a nice straight line using a suitable angle grinder and diamond blade. This leaves a nice clean straight joint as per the original slab.Please contact Polycote Technical Helpline for advice and the appropriate Data Sheets.The prepared joint can then be part filled Polycote Foam Backing Rod or kiln dried sand, leaving a minimum depth of 10mm. Tape may be applied to mask the surface each side of the joint during pouring, but this should be removed as soon as material is placed.Jointex® EP does not require a primer.

Mixing:

Having fully prepared the substrate, stir the individual components before mixing together. Add Part ‘B’ to Part ‘A’ and thoroughly mix for at least 3 minutes. For best results use a heavy duty slow speed drill with a small mixing paddle. Ensure thorough mixing as an unmixed product will result in a poor or non-cure situation.

Application:

Apply immediately using a jug or suitable container to pour the mix directly into the joint. For a professional finish and maximum joint protection, fill to slightly above the level of the surrounding area, but not to the point of overflow. Once cured, (but BEFORE it is too hard!!) the resin may be knifed flush to the level of the floor.

Technical Data Sheet

Technical Data Sheet