Crackfiller EP100 is a solvent-free two-part epoxy resin based system with a free flowing formulation designed to penetrate cracks and gaps, rapidly achieving mechanical strength several times that of high quality concrete.Approx coverage at 3mm x 10mm:

1kg = 33 linear metres

2.5kg = 82.5 linear metres

TIP. You may be interested to note that if the crack is extremely wide or deep, that kiln dried sand (commonly used as block paving sand) can be either poured into the hole first, leaving 5-10mm down from the top) or can be mixed in to the resin to form a type of mortar. Please do remember though that should the crack be thin, it is best to pour the resin neat so that it does indeed penetrate well into the said crack.

IMPORTANT. Is the said crack really a structural crack? If it is irregular and ‘wiggly’ then it is most probably a structural crack. However, if it is in a dead straight line, then it may well be a ‘day joint’ (a natural joint between two individually poured slabs of concrete) or even an expansion joint. If it is either of these, it is in fact very important that you fill these joints with a flexible filler, otherwise the concrete is only likely to crack again. If you are not sure perhaps you might light to see one of our very helpful guides on this subject in our expert centre – ‘How to tell the difference between an expansion joint and a structural crack’.

Pot life:20 mins @ 20oC

Application room temperature:10oC – 30oC

Application substrate temperature:3oC above dew point

Application humdity:Must not exceed 80%

Initial curing time:4-6 hours

Accepts traffic:12-18 hours

Full cure:7 days

Depth of repair (1 layer):0.1mm – 400mm

Fully cured compressive strength:70N/mm2

Fully cured flexural strength:92N/mm2

Fully cured tensile strength:50N/mm2

Fully cured elastic modulus:3.4KN/mm2

Density:1.12g/cm3

VOC content:Less than 200g/l

Number of parts supplied:2

Priming required:No

Please consult the technical data sheet for full technical product data.

Preparation:Thorough substrate preparation is essential.The substrate should be clean and free from dust or oil contamination. For best results the surface should be dry but Crackfiller EP100 will tolerate damp surfaces. A gas torch may help to remove oil or moisture from the surface and clean, dry compressed air may be used to blow out small cracks.

Mixing:

Having fully prepared the substrate, thoroughly stir the contents of Part ‘A’, then pour all of the hardener Part ‘B’ into the pot containing resin Part ‘A’ and mix thoroughly for several minutes using a low speed electric drill until a clear homogenous mix is obtained.

Keep all components at room temperature for 24 hours before use.

Application:

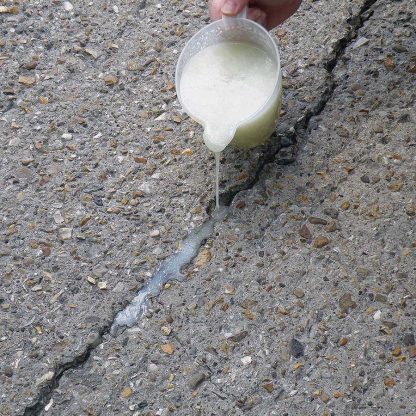

The materials should be poured into the crack immediately after mixing, using a jug or suitable pouring vessel. A bead of caulk/sealant may be applied temporarily along each side of the crack to prevent the flow of the material onto the surrounding area. Surplus mixed material may generate considerable heat within the container at the end of the pot life. Any unused material is best mixed with sand to reduce the heat output before discarding.

Technical Data Sheet

Technical Data Sheet