Pot life:Standard: 15-20 mins @ 10°C

CSG: 15-20 mins @ -10°C

Application temperature:Standard: 0°C – +30°C

CSG: -30°C – 0°C

Initial cure time:1-1.5 hours

Full strength cure time:2 hours

Full compressive strength:75N/mm2

Full tensile strength:7.6N/mm2

Full flexural strength:24N/mm2

Number of parts supplied:2

Coverage:15-20 sq.m. per 5kgs unit

Please consult the technical data sheet for full technical product data.

Preparation:

Thorough substrate preparation is essential.

Powerfloated concrete – use a Vacuum Assisted Shotblaster to remove weak laitence and provide a surface key for the coating. If this is not possible, chemically etch with Polycote Etch IT then rinse thoroughly and allow to dry.

Loose paint – remove, using a Vacuum Assisted Shotblaster, Floor Grinder or equivalent method.

Loose or friable concrete – use a Vacuum Assisted Shotblaster. If this is not possible, chemically clean with Polycote Etch IT then rinse thoroughly and allow to dry.

Oil or grease – use Hot Compressed Air for large areas of contamination. Smaller, isolated deposits may be chemically cleaned with Polycote Degrease IT, then rinsed thoroughly and allowed to dry.

See relevant Data Sheet prior to application.

Once prepared, the area must be kept clean and free of traffic.

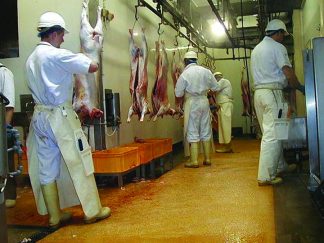

Caution – MC Primer is methyl methacrylate based and has a characteristic odour during the vaporising of the solvent. Although non-toxic and non-injurious to health, this can cause tainting and OPEN food products should therefore be removed or sealed during and following application until the vapour has dispersed.

Mixing:

Before mixing this product you must be totally prepared; for rapid uninterrupted application of the complete mixed quantity within 10 minutes. Having fully prepared the substrate, add part ‘B’ to part ‘A’ and thoroughly mix for at least 3 minutes. For best results use a heavy duty slow speed drill with a mixing paddle.

Ensure thorough mixing as an unmixed product will result in a poor or non-cure situation.

Application:

Apply by brush, roller or squeegee, making sure that the surface is completely covered. Particular attention should be given to doorways and other areas of high traffic. When finished, do NOT scrape the remaining contents from the container as this will invariably include unmixed raw resin.

When priming for Flortex MC – it is advisable to scatter kiln dried quartz aggregate (0.3 – 0.6mm) into the wet MC Primer coating at a rate if 1kg/m2 to increase adhesion of the repair material.

Technical Data Sheet

Technical Data Sheet