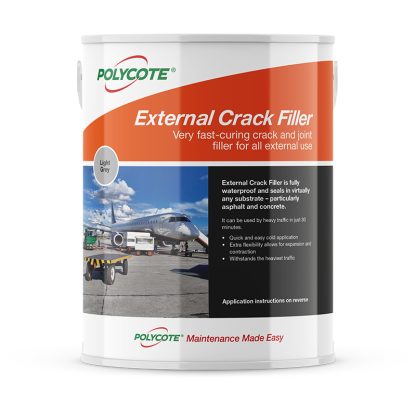

Polycote External Crackfiller is fully waterproof and has been professionally developed to both fill and seal cracks and joints, in virtually any substrate – particularly asphalt and concrete. This is well proven in roads, at airports and sea port, from multi story car parks to concrete yards and paths. the curing process is extremely fast and it is very advisable to use the drawbox so that one person can mix and pour into the draw box and person no two can continuously pull the drawbox along the length of the crack(s)

Being impervious, External Crackfiller also serves well to prevent and water penetration and the washing out of the aggregates below the slab. One can see many many slabs that have cracked across the corner and this is mostly attributable to exactly this problem. The rain, etc, penetrates the joints and washes out the aggregate from underneath creating a weak void. Furthermore, to seal the joint also prevents any further damage from plant growth and / or root attack.

No specialist hot works or heating equipment is needed

Use on: Asphalt, concrete, macadam and tarmac

Use where:External

Type of job: Filling external cracks and expansion joints

Approximate coverage:25kg unit – 110 linear metres @ 6mm(w) x 20mm (d)

Cure time:Cure time – 10 – 40 mins depending on temperature. See technical datasheet for full details

Special features: Heavy duty, chemical resistant, impact resistant and abrasion resistant

Pot life:5 – 15 mins (temperature dependent)

Application temperature:0oC – 30oC

Number of parts supplied:2

Priming required:No

Please consult the technical data sheet for full technical product data.

Preparation:

Thorough substrate preparation is essential.

The surface to be treated must be clean and dry. Use a stiff brush or compressed air to clear the crack of all dirt, standing water and loose material.

Mixing:

Ensure the area to be treated is fully prepared before starting the mixing operation. Stir the resin thoroughly immediately prior to use. Whilst continuing to stir add the powder catalyst and mix thoroughly for a further 30 seconds, scraping around the sides to ensure the catalyst is fully dispersed. This initiates the working life during which time the crackfiller must be used. The pot life is only 5 – 15 minutes so without stopping, move quickly on to applying the material.

Application:

Pour the mixed material in to the draw box and pull it over the surface to fill the crack or joint leaving an even band of material. Keep the draw box level and flat on the ground at all times. Towards the end of the working life polymerisation starts, the viscosity increases (i.e. it becomes stiffer, the temperature rises and the material will start to gel). Do not try to place or work the material further. Discard the remaining material and clean tools quickly.

Technical Data Sheet

Technical Data Sheet