A flexible concrete floor levelling compound specifically formulated to be one of the easiest products to use for levelling rough or damaged concrete flooring – also perfect for expansion joint repairs. Its exceedingly high strength ensures that Easipatch will withstand even the heaviest traffic and the fact that it will achieve 40N/mm2 in only 2 hours means almost zero downtime.

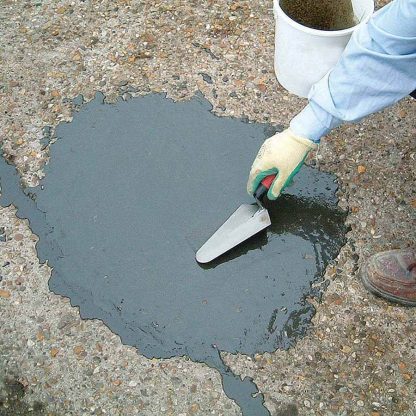

If you look carefully, you can see some ‘drips’ of Easipatch just above the main repair. One of these was hit with a hammer and bolster and the easipatch did not come off the stone underneath. It simply took the stone itself clean out of the concrete! Being like a soup consistancy, Easipatch can be poured onto the affected area of worn, ridged or pitted concrete and simply smoothed out using anything from a wooden ‘straight edge’ to a steel trowel.

You really can lay this as thin as you like – it’s unbelievable AND rock hard! However, do please note that due to its fluidity, this product will not ramp. If ramping is required, please see other products in the Cretex Range such as Cretex EP for instance. Alternatively, give us a ring on Freephone 0800 980 0852 and we’ll be only too pleased to help.

Pot life: 8-12 mins

Application temperature: 5oC – 35oC

Depth of repair (1 layer): Feather edge – 25mm

Initial cure time: 30 mins

Full strength cure time: 1 day

Full compressive strength: 40N/mm2 in 2 hours

80N/mm2 in 1 day

Full tensile strength: 17N/mm2 in 7 days

Number of parts supplied: 2

Coverage: 4.35kg unit – 1.2m2 @ 2mm

Priming required: No

Please consult the technical data sheet for full technical product data.

Preparation:

Thorough substrate preparation is essential.

Remove all loose material – wire brushing is advisable. Sweep clean or vacuum. The surface must be free from grease or oil. A gas torch will help to remove oil from the surface. If this is not practical, Polycote Degrease It may be used to clean the area but this must be thoroughly rinsed off before applying Easipatch™ . Easipatch™ must only be applied to dry surfaces.

Mixing:

Having prepared the substrate, simply mix the premeasured parts A and B together.Ensure thorough mixing as an unmixed product will result in a poor or non-cure situation.If part-mixing is required, please contact the Polycote Technical Helpline.

Application:

Apply by trowel, wearing suitable protective gloves. Smoothing may be assisted by wetting the trowel using Polycote Solvent Cleaner as a release agent.

Technical Data Sheet

Technical Data Sheet