p>Jointex XFH is specially formulated to achieve a rapid cure at ambient temperatures, reducing downtime to only 1 hour. It’s high strength and excellent elongation characteristics offer a heavy duty finish with up to 100% movement within the joint.

Use on:Concrete, metal, stone, asphalt/tarmac

Use where:Internal/External

Typical industries:Any industry with a 24 hour working environment

Type of job:Filling/repairing concrete expansion or construction joints

Approximate coverage:4 kg unit – 29 Linear metres @ 10 x 10mm

Cure time: traffic 1 hour @ 20oC

Special features: High strength, extra flexibility, fast curing

Pot life:10 – 15 mins @ 20oC

Application temperature:0oC to 30oC

Depth of repair: 10mm – 25mm

Number of parts supplied:2

Priming required:No

Please consult the technical data sheet for full technical product data.

Preparation:

Thorough substrate preparation is essential.

All joints must be clean, dry and free of dust, loose material or previous joint sealant. The use of a heat gun may help to remove oil or moisture from the surface.

If the edges have broken away – repair using Polycote Cretex® EP. Cretex® MC may be used if a faster cure is required. Depending on the extent of the repair, the Cretex material may be supported using a thin polythene covered batten until firm, or the joint may be totally filled with Cretex® EP and then re-cut with using a suitable disc cutter in order to provide a clean edged joint. Please contact Polycote Technical Helpline for advice and the appropriate Data Sheets.

Priming:

Jointex™ XFH does not normally require a primer, unless the substrate is very porous, in which case Polycote MC Primer Std can be used.

Deep Joints:

If the joint is particularly deep, then the joint can be filled with either Polycote Foam Backing Rod, which indeed is the cleanest and quickest. Alternatively, kild dried sand can be poured into the joint. Should this be the preferred method, ensure the shoulders of the joint are clean and free of dust prior to the pouring in of the Jointex product.

Whichever ‘filling’ method that is used, please make sure there is at least a 10-15mm depth left at the top for the relevent Jointex product that is to be used. Tape may be applied to mask the surface each side of the joint during pouring, but this should be removed as soon as material is placed.

Caution:

Jointex™ XFH does have an odour whilst curing. Although non-toxic and non-injurious to health, this can cause tainting and OPEN food products should therefore be removed or sealed during and following application until the vapour has dispersed.

Mixing:

Empty the resin Part ‘A’ into a clean plastic mixing container and add the complete quantity of filler Part ‘B’. Mix thoroughly to ensure complete dispersion of the hardener. For best results use a heavy duty slow speed drill with a mixing paddle.

Ensure thorough mixing as an unmixed product will result in a poor or non-cure situation.

Application:

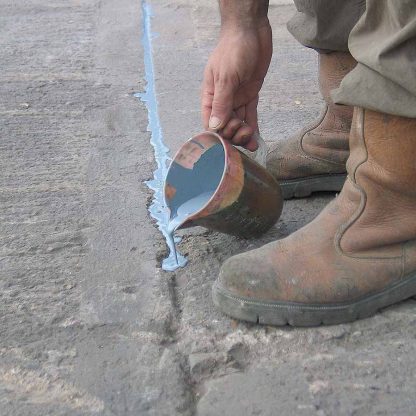

Apply immediately using a jug or suitable container to pour the mix directly into the joint.

For a professional finish and maximum joint protection, fill to slightly above the level of the surrounding area, but not to the point of overflow. Once cured, the top of the filler may be chiselled flush to the level of the floor.