Polycote® Slip Grip is an easy-to-apply, fast curing, slip resistant coating for areas of severe slip hazards.

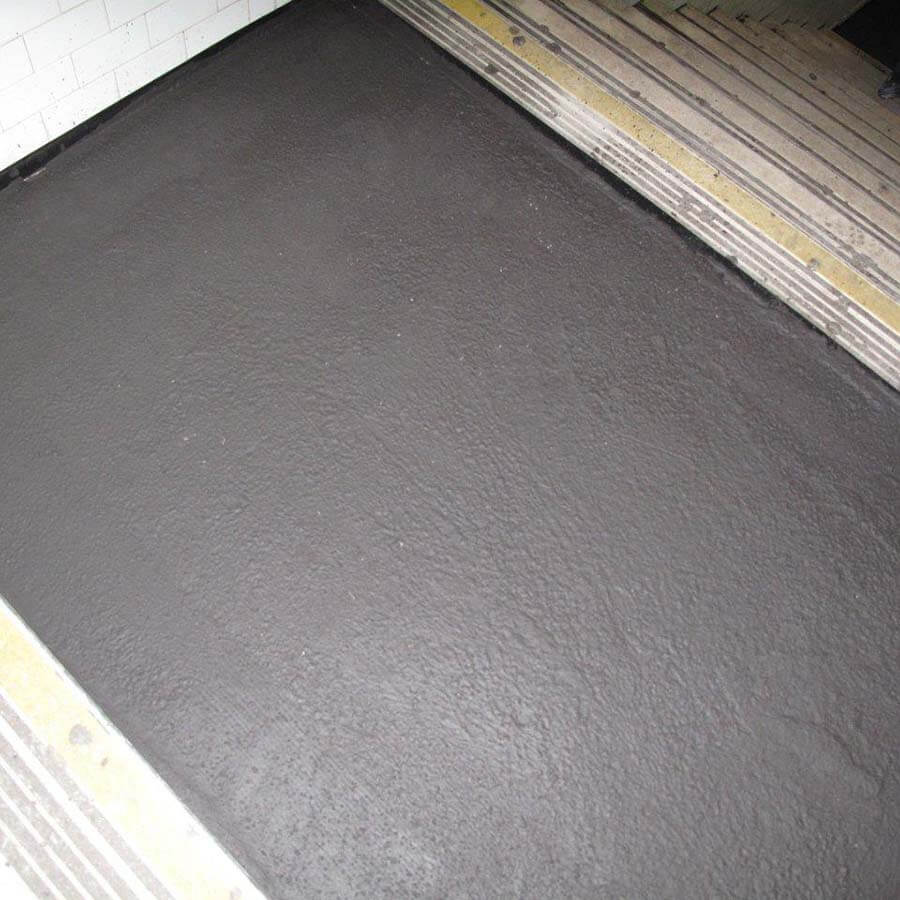

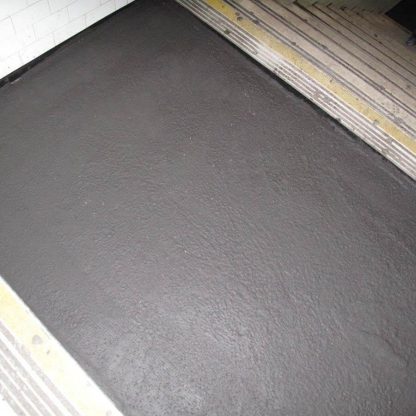

A thickly applied 100% solids resin with tenacious grip. Its coarse anti-slip aggregate provides the top level of slip resistance for areas of severe slip hazards.

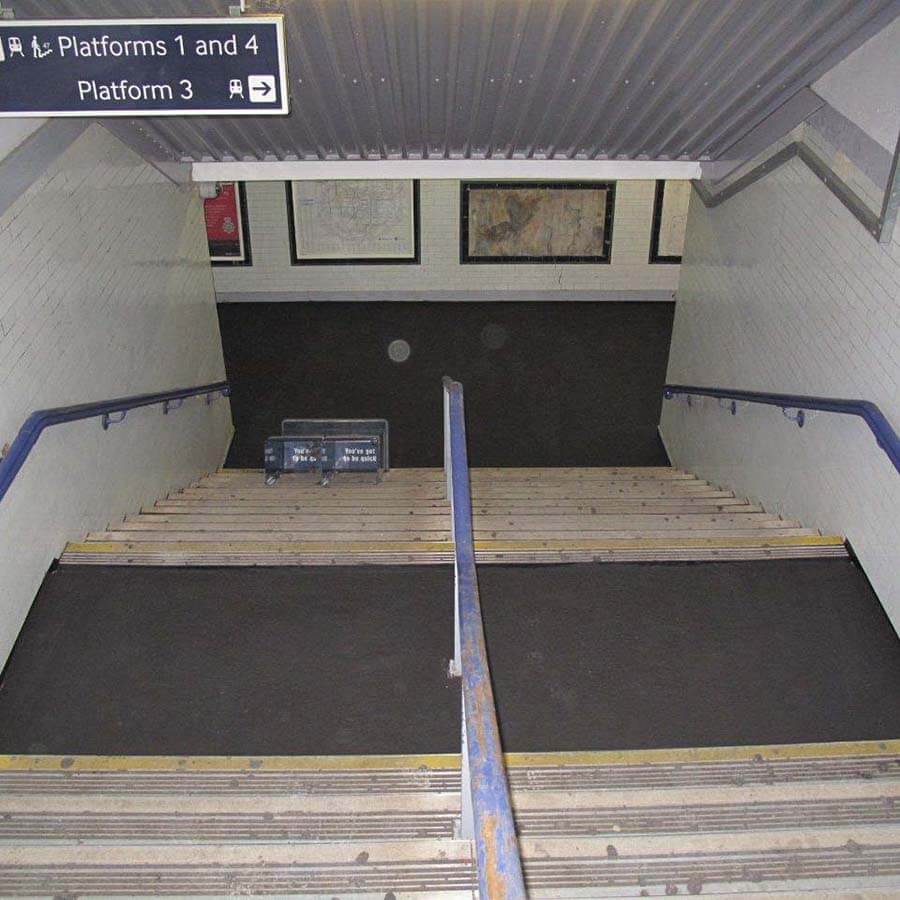

Applied as a single coat, which is then completely broadcast with our unrivalled aggregate for an ultra tough, long lasting non-slip surface. It has amazing ageing properties, is UV resistant and is excellent where demarcation is needed. Slip Grip can be applied at low temperatures, so that no heating is required, and will cure rapidly providing excellent flexibility even at those low temperatures.

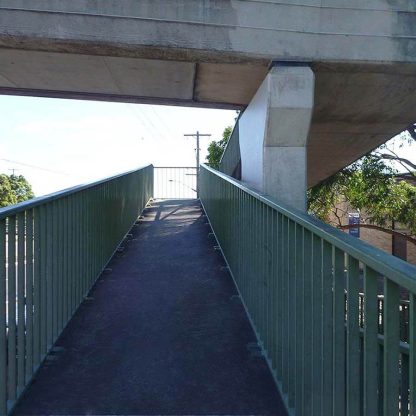

Excellent for those individual areas such as high wear ramps, steps on machinery and vehicles, plant and equipment. Typically used on roads, cycle routes, walkways, traffic calming zones, parking bays etc. Slip Grip can be trafficked within one hour and is supplied in a range of colours.

There are two grades available, depending upon time of year: Winter Grade and Summer Grade.

Number of parts:2

Pot Life at 20oC:12 mins

Application Temperature:0oC to 35oC

Curing Time at 20oC:40 minutes

Coverage:15kg – 4 – 7.5 sq.m.

30kg – 9 – 15 sq.m.

Please consult the technical data sheet for full technical product data.

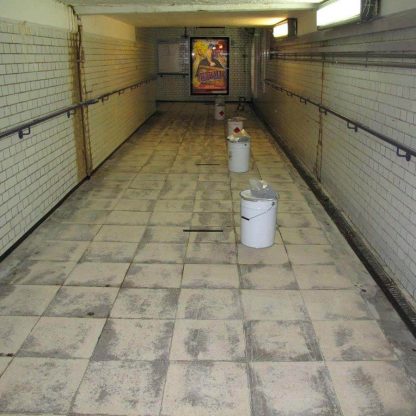

Preparation:Thorough substrate preparation is essential.

All surfaces should be free from all contamination such as de-icing salts, grease or oil, any loose or friable particles, moss or algae growth, dirt and frost. Grease and oil should be removed using our Polycote Degrease IT.

CONCRETE: Concrete surfaces must be prepared using mechanical preparation; this can be done with a vacuum assisted shotblaster, floor grinder or equivalent method. Please note that water jetting will not key the surface suitably. All repairs should be made prior to application using one of our concrete repair products. We advise that you then prime the surface with one of our Polycote Primers, however this is not essential.

ASPHALT: Again, the surface must be clean, dry and sound. For applications onto asphalt less than 28 days old, atest area should be carried out; this should cover all variations in the asphalt substrate. A circular area of about 100mm in diameter and about 5mm thick should be laid. Once this has cured, its adhesion should be tested with a hammer and bolster; if the product comes up, the asphalt will have to be left until it is 28 days old. The asphalt can be dried using a hot compressed air lance. The surface will not need priming.

STEEL: The steel should be exposed to a bright metal, all rust, dirt, oil, grease and contamination should be removed. The steel should be primed, please contact one of the Polycote technical advisers for the correct product.

MIXING: Having fully prepared the substrate, stir the resin part thoroughly. Settlement will have occurred during storage and transportation and you should continue mixing until the product has fully homogenised. Add the aggregate and mix until it is totally stirred in. The hardener should now be added and mixed until it has dispersed; this should not take more than 1 minute. For best results use a heavy duty slow speed drill with a mixing paddle. Please note that adding the hardener starts the chemical reaction. Ensure thorough mixing as an unmixed product will result in a poor or non-cure situation.

APPLICATIO:

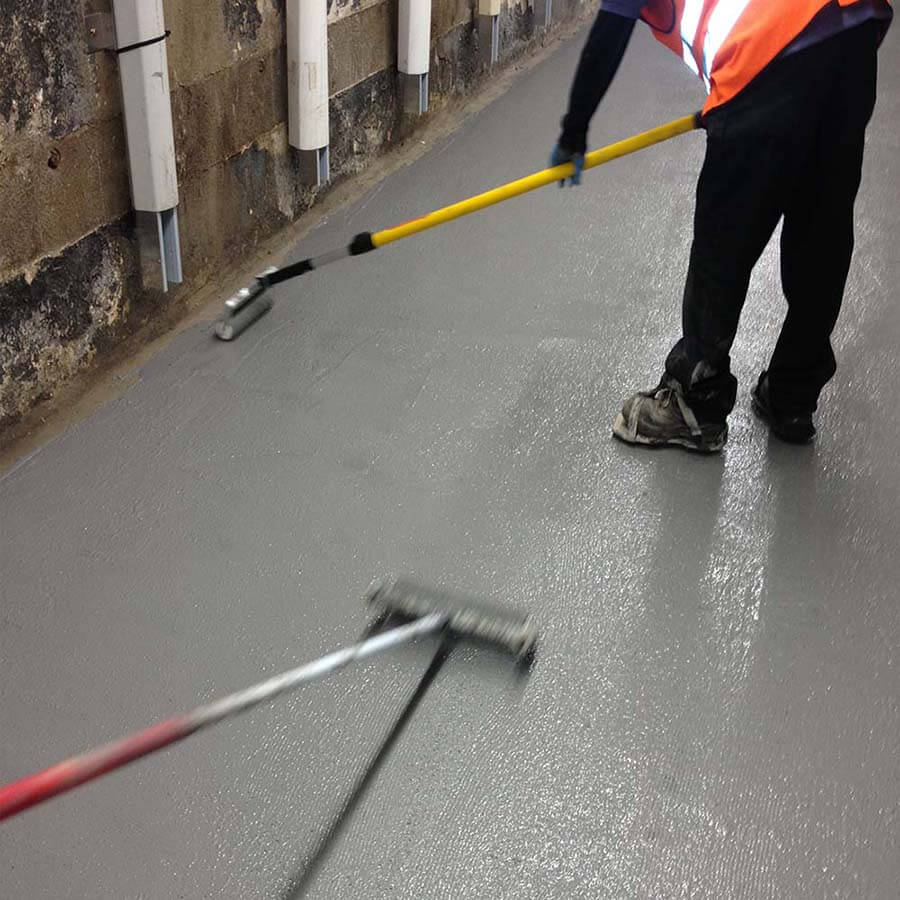

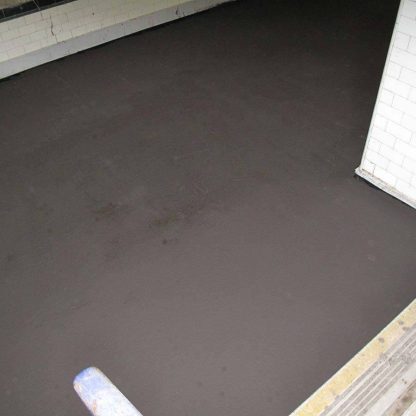

The application of Slip Grip is very fast and everything must be ready before you start.

The product should be laid at about 4mm using a serrated squeegee followed by a roller. The roller application should be perpendicular to the squeegee application (crossrolled). A medium pile roller should be used which can be supplied by Polycote UK. Once applied allow to fully cure before trafficking.