Typical Uses:

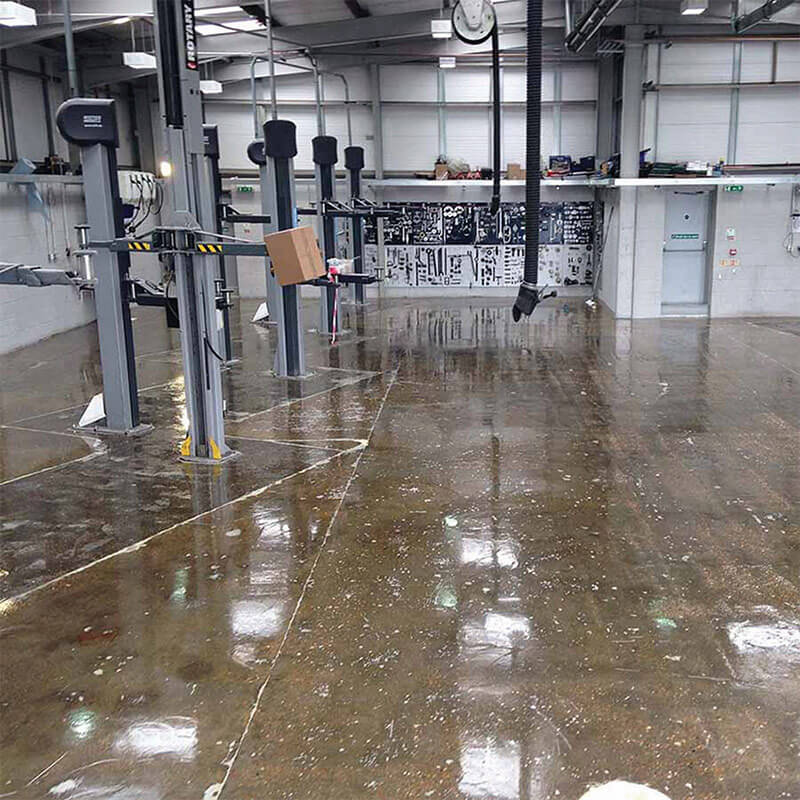

OT Primer XFH is a system for sealing oil impregnated or permanently damp concrete floors. It is not in itself a coating or floor paint, and must always be over-coated with an appropriate top coat.

OT Primer XFH is a solvent-free, low viscosity, high solids content twin pack epoxy resin with oil binding and water-reactive properties. Designed for application to open pored damp and oily surfaces, OT Primer XFH is highly resistant to rear side soaking from both oil and water, allowing the most difficult of floors to be coated.

OT Primer XFH is ideally suited to heavy engineering plants and car and truck service depots. It can also be used in any place requiring minimal downtime.

Number of parts:2

Application Temperature:8oC to 25oC

Pot Life (at 20oC):20 minutes

Initial Cure:6 – 8 hours

Full Cure:2 – 3 days

Coverage:3.7kg – 10-15m2

7.4kg – 20-30m2

Please consult the technical data sheet for full technical product data.

Preparation:Thorough substrate preparation is essential.

The surface must be free of brittle particles and laitence. Any remains of previous coatings should be removed by means of scabbling, shotblasting and/or diamond grinding. Oil and grease build up should be removed using high pressure hot water or steam jet, to fully expose the substrate.

Important: Free pores must be exposed to ensure good adhesion to the surface.

All water must be removed from the surface, leaving it damp but not wet. OT Primer XFH™ may then be applied to the damp surface immediately after cleaning.

Mixing:

Mix only as much as can be applied within the pot life (see ‘Pot Life and Curing Time’). Add part ‘A’ to part ‘B’ in a suitable container, and thoroughly mix for at least 3 minutes. For best results use a slow speed drill with a mixing paddle, making sure all material from the sides and bottom of the container are thoroughly mixed in and a homogeneous mix is obtained.

Ensure thorough mixing as an unmixed product will result in a poor or non-cure situation.

Application:

Apply by brush, roller, or squeegee, in one or more continuous applications until the material is absorbed and a film has formed. Make certain that the entire surface is completely covered to prevent oil or water migration. Oil or grease impregnated surfaces are best primed with a paint brush or soft sweeping broom, in order to ensure the primer is worked well into the surface.

Allow to fully cure before the application of any further coating.

Whilst this is in fact extremely rare, it is important to note that if contamination is particularly bad, the substrate may require a further coat of OT Primer XFH.

Re. Self-Levelling Cementitous Screeds.

Should the intention be to pour a cementitous screed (Polycote Easi-Screed) over the primer, then it is important to broadcast kiln dried sand over the primer to ensure an intercoat adhesion is achieved between the primer and the screed.

Ensure Aggregate should be sprinkled evenly over the OT Primer XFH whist it is still WET, at a rate of 1kg per m². (Spiked shoes may be worn to avoid disturbing the wet coating).

Allow to cure for a further 24 hours before removing any loose / excess aggregate from the surface, which is then ready to receive the desired Easi-Screed product.

Where dampness and/or oil contamination is of particular concern, it is advisable to seal the surface completely with one first coat of OT Primer XFH and then to lay a second coat onto which the aggregate would then be applied. The reason for this is to ensure there is no ‘bleed through’, should any particles of aggregate penetrate the primer. (Whilst any such penetration is in fact extremely unlikely, some companies with strict requirements / constraints prefer the certainty of a 100% seal, prior to any aggregate being applied).

Finally, please be free to consult our Technical Department, who will be more than happy to help with any specific requirement / concern.

Technical Data Sheet

Technical Data Sheet