Flortex PU Screed is the ultimate floor screed – professionally developed to provide the ultimate hygienic barrier and resistance to relentless chemical attack, impact and abrasion, thermal shock and impermeability.

Use on: Concrete. For other substances contact Polycote Experts.

Use where: Internal/External

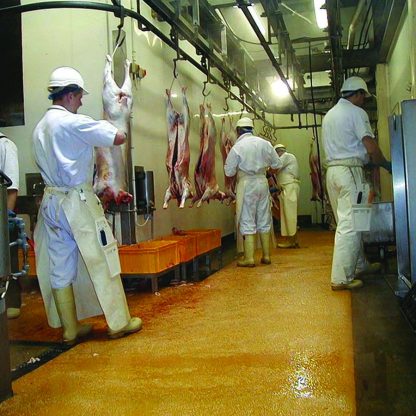

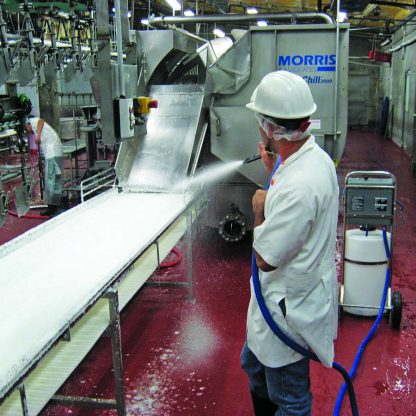

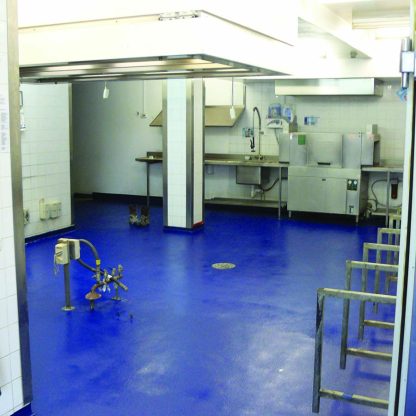

Typical industries: Chemical plants, food processing plants, engineering, shipping and transportation, pharmaceutical, aerospace, off-shore oil platforms

Type of job: Heavy duty industrial areas requiring a seamless, professional finish which also protects plinths, bases, walls, kerbs, sumps and pits from physical attack as well as a completely impervious ‘bund’ resistance to biocidal, microbiological and chemical attack

Approximate coverage:2.5m2 @ 6mm, 1.67m2 @ 9mm

Cure time: Initial Cure 4 – 6 hours@ 20oC

Light traffic 12 – 16 hours@ 20oC

Heavy duty traffic – 48 hours

Full chemical cure – 3 – 5 days

Special features: Heavy duty, chemical resistant, impact resistant, abrasion resistant, long lasting anti-slip finish, can be steam cleaned, zero permeability, withstands temperatures from +120oC in bakeries to -35oC in cold stores

We strongly recommend that this product is installed only by our fully trained and highly skilled tradesmen. We offer a nationwide competitive, reliable and professional service. Please call our Technical Sales team to discuss your project.

Pot life:15 mins @ 20oC

Application temperature:5oC – 20oC

Depth of screed (1 layer):6mm – 9mm

Initial cure:4 – 6 hours

Light traffic:12 – 16 hours

Full traffic:48 hours

Number of parts supplied:3

Please consult the technical data sheet for full technical product data.

Preparation:

Thorough substrate preparation is essential.All substrates must be clean, sound, dry and free of surface laitance.Recommended methods are:• Powerfloated concrete – use a Vacuum Assisted Shotblaster to remove weak laitance and provide a surface key for the coating. If this is not possible, chemically etch with Polycote Etch IT, then rinse thoroughly and allow to dry.• Loose paint or rust – remove, using a Vacuum Assisted Shotblaster, Floor Grinder or equivalent method.• Loose or friable concrete – use a Vacuum Assisted Shotblaster. If this is not possible, chemically clean with Polycote Etch IT then rinse thoroughly and allow to dry.• Metal – use a shot-blaster to prepare the surface to SA2.5 (bright steel) and primed with ZP Primer.Deckplates of 4mm or less do not provide a sufficient substrate for Flortex PU Screed, please contact Polycote Technical Helpline for further information.To give a professional finish, we advise that grooves are cut into the floor around the perimeter of the substrate, to give the screed an anchorage. The groove should be about 20mm wide and 8mm deep and about 150mm from the edge

Mixing:

Once the surface has been thoroughly prepared, a suitable primer has been applied, and the surface is tack free, apply Flortex PU Screed.Stir the individual components before mixing together. Add Part ‘B’ to Part ‘A’ and thoroughly mix for at least 1 minute. Steadily add the aggregate whilst continuing to mix. Mix thoroughly for 3 minutes once all the aggregate has been added.For best results use a heavy duty slow speed drill with a mixing paddle. Ensure thorough mixing as an unmixed product will result in a poor or non-cure situation.

Application:

Once fully mixed, apply the product between the battens (if necessary) and level with a steel float. If a smooth finish is required (to assist cleaning), back-roll with a short pile roller.

Technical Data Sheet

Technical Data Sheet