Easi-Screed External is a highly specialised self-levelling concrete resurfacer designed to cope with the stresses of weathering. Easily applied, it withstands expansion and contraction caused by hot or cold, dry or wet weather conditions.

Use on: Concrete. For other substances contact Polycote Experts.

Use where:External

Approximate coverage: 10 kg unit – 1.6m2 @ 7mm average thickness

Cure time: Pedestrian traffic – 6 hours @ 20°C

Light wheeled traffic – 24 hours

Heavy duty traffic – 48 hours

Special features: Heavy duty, chemical resistant, impact resistant, abrasion resistant, can be feather edged

Pot life:15 mins @ 20oC

Application temperature:5oC – 20oC

Depth of repair (1 layer):5mm – 15mm

Initial curing time (light foot traffic):3 hours @ 20oC

Initial curing time (light foot traffic):24 hours @ 5oNumber of parts supplied:2

Priming required:Concrete or sand and cement screeds – Dampen surface using water.

Non-absorbent surfaces – prime with Polycote WD Primer.

Please consult the technical data sheet for full technical product data.

Preparation:Thorough substrate preparation is essential.Follow recommendations given on the relevant primer Data Sheet.See ‘Priming’ below for the primer appropriate to your application.

Priming:Concrete or sand and cement screeds – prime with Polycote Easi-Screed Primer.Non-absorbent surfaces – prime with Polycote WD Primer.Oily/contaminated surfaces – prime with Polycote OT PrimerDamaged DPM / Rising damp issues – prime with Polycote DPM PrimerPlease refer to relevant Data Sheets for preparation and priming methods.

Mixing:

Measure 4.5L of clean water into a suitable sized bucket.Gradually add the entire 25kg quantity of powder whilst mixing with a heavy duty slow speed drill and mixing paddle. Mixing by hand does not readily give a thoroughly or evenly mixed product.Mix for at least one minute to allow the additives to dissolve and produce a homogenous mix which should be lump free and a consistency of single cream. When mixed allow to stand for 2 minutes and stir again before application..Do not mix more than can be applied in 25 minutes. Do not add excess water.

Application:

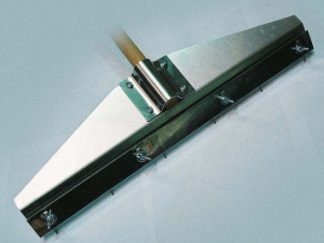

Pour the material evenly onto the floor to the required thickness and allow the material to start levelling.The use of depth adjustable floats or a pinned/notched leveller is recommended to assist in spreading the screed to a constant thickness.A spiked roller should be used immediately over the freshly poured material to eliminate any bubbles trapped within the screed. The next mix of material must be rapidly produced and poured along the wet edge of the material as well as across the exposed floor.Each application should be laid within 20 minutes of the area adjoining in order to blend evenly into the edge of the previously laid material. This can be helped by gently trowelling along the joint.Once the workable time has been exceeded it is not possible for the new material to be blended into previously applied material. Therefore the floor topping should be applied to the entire area in one continuous operation.Application by pump:

Prior to laying the mixed compound carry out a flow test using a flow ring (30mm diameter x 50mm long). A flow diameter of 135mm + or – 10mm should be achieved, adjust mix accordingly to comply to this flow criteria. Periodically check to ensure mix remains in limit. Warning: 1) If the product is not spike rolled immediately and the screed begin to cure, roller spike marks will remain visible. 2) Failure to disperse the air bubbles by spike rolling may result in a lesser impervious finish.3) Do not add excess water

Technical Data Sheet

Technical Data Sheet