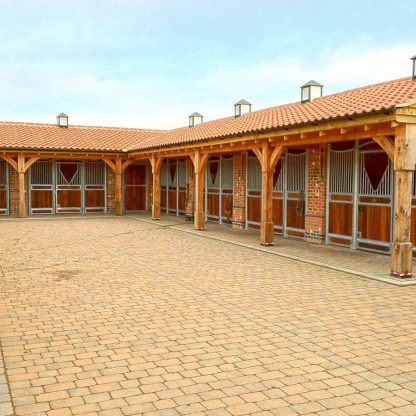

Regularly used in industrial and commercial applications. Block Seal binds the sand and bonds the pavers together, eliminating the problems associated with sand loss caused by vacuum sweepers, jet thrust, pressure washing or flooding.

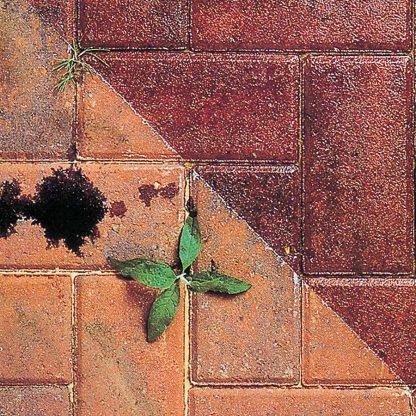

Totally seals surface and bedding sand against oil contamination and prevents unsightly plant growth.

Withstands temperatures in excess of +200oC

Application temperature:10oC – 25oC

Initial cure time:2-3 hours @ 20oC

To accept foot traffic:As soon as it is dry

To accept vehicular traffic:3 days

Number of parts supplied:1

Coverage:12-15 sq.m. per 5L unit

50 sq.m. per 20L unit

Primer required:No

Shelf life:6 months

Storage temperature:10oC – 25oC

Please consult the technical data sheet for full technical product data.

Preparation:

Ensure paving surface is DRY and free of oil and grease, moss and plant growth, dirt and debris.

The following preparations are recommended:

Oil and grease – remove with Polycote Degrease IT, then rinse thoroughly and allow to dry. See relevant Data sheet.

Moss, lichen and fungal growth – remove by stiff broom or jet washing, then treat the area with Polycote Destroy IT – see relevant Data sheet.

Once necessary preparations have been carried out, allow to dry thoroughly and top up joints with kiln dried sand as may be necessary before applying Block Seal.

Application:

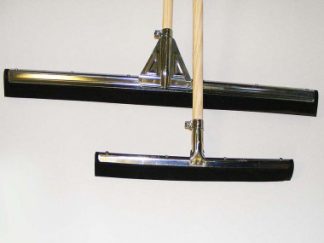

Block Seal is normally applied by squeegee, roller or spray. One or two coats may be required depending on the porosity of the surface. Excess material remaining on the surface of the blocks may be removed whilst wet using a foam roller.

Containers must be kept sealed as the material will evaporate and react with air/humidity. Opened material must be used within 24 hours.

Technical Data Sheet

Technical Data Sheet