Details

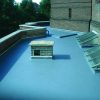

Aquadec is a three stage system comprising of a first coat Aquadec DPM, then a coat of Aquadec Base to build up the thickness and finish it with a coat of the Aquadec Sealer.

Stage 1 Aquadec DPM – This layer is a fast drying, non-toxic, non-taint primer. The product, being single pack, is extremely easy to use and it will easily bridge small cracks. (Please note however, that this will obviously depend the condition of the substrate and the cause of the crack – please refer to Application Sheet for further details). Aquadec will adhere to almost any surface, with excellent adhesion, even if its damp and it’s fast curing formulation means that the primer is touch dry within approximately 1 hour.

Stage 2 Aquadec Base – A polymer/cement based product designed to be applied over a wide range of surfaces to provide a durable surface strongly bonded to the substrate with a degree of flexibility to enable the accommodation of movement in the substrate and structure of the building. Aquadec Base will naturally provide a slip resistant surface.

Stage 3 Aquadec Sealer – This is the final roller applied sealer that provides whatever colour you choose to further enhance the decorative and functional properties of the surface.

Through continued research and listening to customer feedback, Polycote UK has created a 100% waterproofing system that will be the cure to many long standing waterproofing problems, such as balconies, walkways and car park decks as well as basements. Good substrate protection will also be achieved.

Aquadec is ideal for:

- Waterproofing balconies – tiled, asphalt, concrete

- Creating a watertight floor covering around swimming pools

- Sealing the surface under tiles

- Tanking of bathrooms/ wetrooms

- Preventing the buildup of damp in basements

Can be applied to plasterboard, plywood, brick, concrete, asphalt and fiberglass.

Number of parts: 3

Application temperature: 5oC to 25oC

Pot life of Aquadec Base @ 20oC: Approximately 2 hours

Curing time: 4 – 6 hours

Pot life of Aquadec Sealer @ 20oC: Approximately 50 minutes

Curing time: 12-14 hours

Coverage: Packs designed to cover 9sq.m., 18sq.m. or 36sq.m.

Number of base coats: Pedestrian grade: 1 coat

Vehicular grade: 2 coats

Preparation:

Thorough substrate preparation is essential.

The substrate must be sound, clean and free of loose or friable materials, dust, chalk, oil and grease contamination, mould or algae. Remove any oil or grease using Polycote Degrease IT.

Any damaged areas should be repaired and primed – please contact the Polycote Technical Helpline for further advice.

New concrete should be at least 4 weeks old and the weak dusty laitance should be removed using Polycote Etch IT.

Application – Priming:

If applying to steel in damp or corrosive environments, a corrosion inhibitive primer should be applied before application of the membrane.

Application – Aquadec DPM:

Aquadec DPM is a very easy to use, single pack product and simply requires thorough stirring before use.

It is of course vitally important to ensure the product is applied evenly and at the correct spread rates in order to achieve a sufficient dry film thickness to cope with surface tensions, stresses and any such expansion and contraction issues. The product is sold in standard pack sizes to cover 10sq.m, 20sq.m, and 40sq.m. It must be noted however, that if the surface is profiled, this can dramatically increase the surface area to be coated and you will require extra DPM material to allow for this largerl surface area. Equally should the surface be porous, the DPM will be drawn down into the substrate and the resultant surface build may well be insufficient to cater for expansion cracking. Whilst the second DPM coat will most cater for this, extra material may well be required to achieve the surface build necessary. Unfortunately, we cannot say exactly how much will be required as every situation is different. Advice will certainly be given, but it is the responsibility of the user to discern the individual need(s).

As a final point of consideration, please also note that when applying to large areas, the porosity can differ with each pour of concrete, so whereas one area can be good and solid, another area can be completely different and very poor!

Expansion Joints:

When applying over expansion joints, it is advised that the expansion joint be brought through the Aquadec coating and sealed off with a suitable joint sealant. Depending upon the circumstances, Polycote Jointex SP is an excellent product for this purpose. It must be appreciated that should the Aquadec be applied over such a joint, that the joint may well expand and contract over and above the ability of the Aquadec and cause the coating to crack. For your interest and in many cases this does not normally cause a water ingress problem due to the joint itself being sealed and will only be an issue aesthetically.

Cracking:

If the substrate cracks, or when bridging over existing cracks, it is important to note that the Aquadec Base, whilst flexible, does not allow for such expansion and will crack. However, the Aquadec DPM is a very elastic and will allow for minor hairline cracking PROVIDED THAT it has been applied at a thickness sufficient for the said movement. This is why two coats of Aquadec DPM are advised, especially where the existing substrate is porous. It must be realised that the surface build of the Aquadec DPM needs to be of sufficient thickness to allow for expansion and to be able to take up the stresses it is subjected to. With regard top the Aquadec Base, again, surface cracking should not be any great detriment to the product other than from an aesthetic perspective.

Should you have existing cracks, it is advised to fill the cracks prior to the application of the Aquadec System. We are happy to give a couple of options to achieve this but it must be responsibility of the purchaser to establish the cause of the cracking.

1) Drying out / stable cracks. These are where the substrate is stable and are not subjected to further movement, we advise Polycote Crackfiller EP100. This is a 100% solids ultra low viscosity resin that will fill and solidify the crack.

2) Expansion/Contraction cracks. Cracks subjected to movement should always be filled with a jointing material capable of expansion and contraction. To fill with a product that hardens and does NOT allow for such movement will only cause the crack to either reappear in the same place or indeed cause the substrate to crack elsewhere. Bearing that in mind, it is advisable to view the Polycote Jointex Range to find the best solution for your needs.

Application – Aquadec Base:

Before application of Aquadec Base to horizontal or vertical surfaces, ensure that porous surfaces are damp, this can be done simply by spraying a hose / surface mist over the area. The area must only be damp and no puddles should be present, any surface water must be removed.

Please note: all warm surfaces may also be cooled by following this procedure and prior to applying succeeding coats the same procedure will aid the spread of the material.

Mixing:

The ideal mixing tool is a slow speed drill fitted with a multi action mixing paddle. Suitable mixing paddles can be purchased from Polycote.

The unit of material supplied is based on the standard mix of 5 litres of liquid to 12.5 kgs of powder (i.e. 1 part liquid to 2.5 parts of powder).

Pour the liquid into a clean open mixing vessel (e.g. the plastic container used to supply the unit) and always add the powder into the liquid slowly, continually mixing until all the powder to be used is added. Continue mixing for a further 2 to 3 minutes ensuring there are no lumps in the mix. The final consistency should be similar to that of a thick cream. Please Note – the mix will be very light in colour – For black, terracotta and green versions the colour is achieved by the application of the Aquadec Sealer.

Caution: Do not apply Aquadec on hot surfaces or at times of very strong sunlight and high temperatures as this could accelerate the drying of mixed concrete and produce a very rapid cure of the applied material.

Aquadec Base is extremely simple to apply. Apply by brush, roller, trowel or squeegee.

From the mixing vessel pour out a quantity of material that can be easily and uniformly spread using the selected tool over the appropriate area and finish to the desired texture before moving on to the next part of the mix. Repeat the mixing and application method until the selected area has been completed.

Note: The Pedestrian grade will require just one Aquadec Base whereas the Vehicular grade requires two coats. The second coat can be applied once the first coat has dried.

Application – Aquadec Sealer:

Mixing:

The ideal mixing tool is a slow speed drill fitted with a multi action mixing paddle. Suitable mixing paddles can be purchased from Polycote.

The Aquadec Sealer unit is made up of two pre-measured parts and we do not recommend splitting this down to make up smaller units.

Please note: Aquadec Sealer is a balanced formulation and no additional water should be added to the mixture.

Application:

Before application of Aquadec Sealer to horizontal or vertical surfaces, ensure the Aquadec Base is fully cured and surface is clean, solid and dry.

Aquadec Sealer is extremely simple to apply using either a brush and/or a roller.

From the mixing vessel pour out a quantity of material that can be easily and uniformly spread to the desired thickness / coverage rate.

The Aquadec Sealer should not be applied where the air or background temperature is likely to fall below 5oC or where there is a risk of rainfall on exposed applications prior to full curing being achieved.

Technical Data Sheet

Technical Data Sheet