Typical Uses:

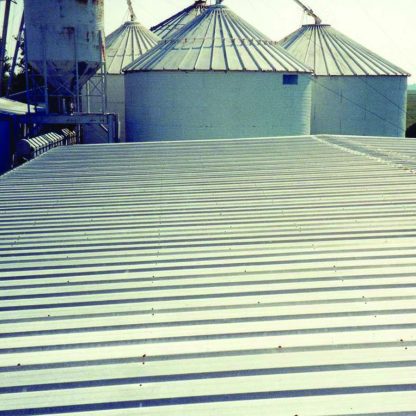

Suitable for both interior and exterior applications. All metal surfaces including roofing, cladding, harbour and offshore decks, structures and cranes, tanks and ducting, cables, nuts and bolts.

Extremely easy to apply by brush or roller, Polydex forms a highly elastic, anti-rust membrane which is impermeable to water and highly resistant to weathering, mechanical and chemical attack. Its specialist formulation includes high quality anti corrosive pigments, achieving a galvanic protection against corrosion.

Number of parts:1

Application temperature:8oC to 55oC

Drying times @ 20oC:Touch dry: 1.5 hours

Rain resistant: 3 hours

Fully cured: 14 days

Coverage:Brush/roller: 2.5m2/kg

Airless spray: 4m2/kg

Number of coats:1

Please consult the technical data sheet for full product technical data.

Preparation:

The surface should be clean, dry, free of all old or flaking coatings, mill scale or loose rust.

The surface has to be dust free and made rust free by means of sandblasting (Sa2, St2) or high pressure water jetting (min. 600 bars). After jetting, the substrate has to be dust free. Oil and grease should be removed using Polycote Degrease™ IT. The surface must be dry and dust-free before coating.

New galvanised surfaces should be primed with ZP Primer. For old galvanised surfaces, plastisol sheeting and smooth concrete prime with 1 coat of Polydex High Build, thinned with 25% water, followed by 1 full coat.

On non-ferrous substrates, use Polydex High Build thinned with 25% water, as a primer coat first.

Application:

Stir thoroughly before use.

Polydex may be applied by brush, roller or airless spray (but not conventional spray gun).

A smooth even finish is best achieved by airless spray application.

Airless spray – use nozzle size 13-17 and 170 bars pressure. During work stoppage, immerse nozzle in water.

Only one coat is required.

Technical Data Sheet

Technical Data Sheet