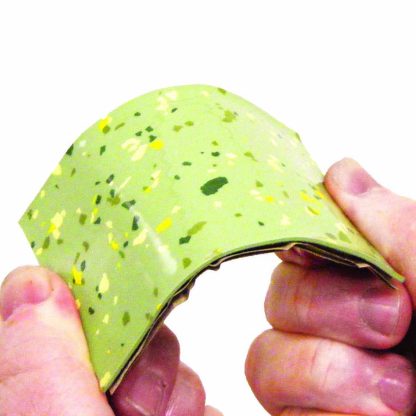

Flortex Flexiset is a hard wearing high build epoxy formulation ideal for use on asphalt and other flexible flooring surfaces.

Use on: Asphalt, concrete, terrazzo, quarry and ceramic tiles, steel and timber.

Use where: Internal/External

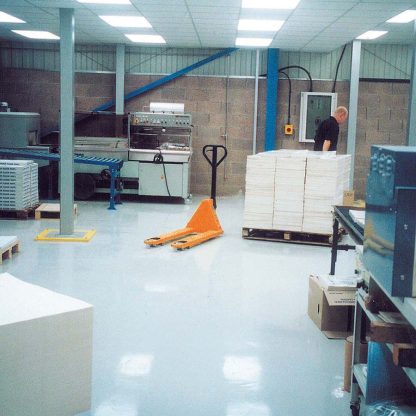

Typical industries: Medical, animal and food processing environments, warehouses, factories, showrooms, aircraft hangers and railway depots

Type of job: Coating of a floor to provide an impervious, high build coloured gloss finish which is provides flexibility and is resistant to forklift traffic

Approximate coverage:15 kg unit – 35 – 45m2

Cure time: Initial cure – 8 – 10 hours @ 20oC

Full cure – 7 days

Special features: Heavy duty, chemical resistant, impact resistant, extra flexibility, impervious finish, easy to clean, abrasion resistant

Pot life:40 mins @ 20oC

Application temperature:10oC – 25oC

Number of parts supplied:2

Priming required:Yes

Please consult the technical data sheet for full technical product data.

Preparation:Thorough substrate preparation is essential.Prior to application of Flortex Flexiset a suitable primer should be applied.

These include Polycote EP Primer, WD Primer or OT Primer, depending on the type and the condition of the surface.

Please contact Polycote Technical Help line, and prepare the surface in accordance with the appropriate primer data sheet.

Mixing:

Having fully prepared the substrate, stir the individual components before mixing together. Add Part ‘B’ to Part ‘A’ and thoroughly mix for at least 3 minutes. For best results use a heavy duty slow speed drill with a mixing paddle.

Ensure thorough mixing as an unmixed product will result in a poor or non-cure situation.

Application:

Flortex Flexiset may be applied by brush, roller or squeegee, depending on the film thickness required.

To achieve a smooth high build finish – apply Flortex Flexiset at a rate of 0.3kg to 1kg per 1m2 using a roller or squeegee.

When the quantity of resin used exceeds 0.5kgm2, air bubbles may become trapped in the coating. These are removed by using a Polycote Spiked Roller and must be carried out immediately after application of the resin before curing takes place. Spiked shoes should also be worn to avoid disturbing the wet coating.

To achieve a high build or textured finish – having applied the resin at a rate of 0.5kg to 1.0kg/m2, then gradually sprinkle 0.3-0.6mm Kiln Dried Aggregate onto the WET resin at a rate of 2-4kg/m2.

The quantity of the aggregate required will depend on the thickness of the initial coating. If a textured surface is required, all ‘wet spots’ must be re-covered with aggregate.

Please note: spiked rolling is unnecessary for the first coat when using aggregate.

Allow first coat to fully cure (preferably 24 hours) before removing all excess aggregate.

A final coat of Flortex Flexiset should then be applied using a roller or squeegee. The thickness of this coat may be varied depending on the finish required.

Technical Data Sheet

Technical Data Sheet