The incredible strength of DuraGrid ensures complete safety and is ideal for heavy traffic.

Totally chemical and corrosion resistant, ensures extremely long life with areas still in heavy use after 16 years.

High flexural strength allows the retention of shape immediately after the cause of stress is removed.

Easily cut to any size or shape – please ask

Incredible strength to weight ratio

Safe working load deflections (per 1200kgs loading)

25mm – 3.55mm (with support spans @ 450mm)

38mm – 1.01mm (with support spans @ 450mm)

Typical Uses:

DuraGrid is ideal for factories, workshops, refineries, distilleries, kitchens, off-shore platforms, chemical plants, beverage plants, and any locality where safety of footing is paramount.

Cutting:

DuraGrid can be cut to size using a skill saw with a diamond blade (4mm), or alternatively using an angle grinder (1mm blade).

Before fixing any of the DuraGrid products, place them in their respective positions to ensure that they fit freely and that the finish will be neat.

Installation:

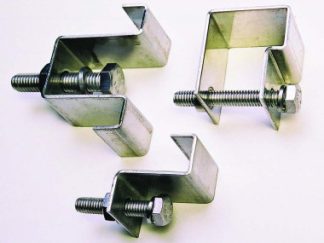

Standard Clips – There are three common types of standard clip made in 316 stainless steel used for fixing grating panels: type M, type L and type C.

Type L: Clips – for use in securing grating to support frames.

Type M: Hold Down Clips – designed to fix grating on support structure and prevent it from turning.

Type C: Clips – applied to connect two adjacent grating bars.