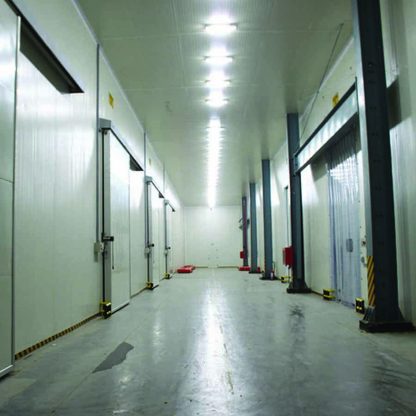

Formulated primarily for coldstores, Cretex MC is extremely strong and ideal for heavy duty repairs where curing must take place extremely fast.

Ready for traffic after only 45 minutes

Incredible 75N/mm2 compressive strength after 2 hrs

Will feather-edge with superb impact resistance

Ideal for cold stores, fridges and freezers

For porous areas, prime the surface with MC Primer followed by Cretex MC Standard (Std) or Cretex MC Cold Store Grade (CSG).For thicker applications (15-50mm) use the Deepfill version.Where the temperature is above 0°C, use the Standard versions, however if the temperature is below 0°C, use the Cold Store Grade. Please note: you cannot use the standard version below 0°C, and you cannot use the Cold Store Grade above 0°C – they WILL NOT cure. If you are uncertain of the best solution, please speak to our technical department.Coverage:

Standard: 1 sq.m. @ 8mm thickDeepfill: 1 sq.m. @ 12.5mm thickPrimer: 10-20 sq.m.

Pot life:Standard: 15-20 mins @ 10°C

CSG: 15-20 mins @ -10°C

Application temperature:Standard: 0oC – 30°C

CSG: -40oC – 0°C

Depth of repair (1 layer):Standard: Feather edge – 15mm

Deepfil: 15mm – 50mm

Initial cure time:45 mins

Full strength cure time:2 hours

Full compressive strength:75N/mm2

Full tensile strength:7.6N/mm2

Full flexural strength:24N/mm2

Number of parts supplied:2

Coverage:16kg unit – 1m2 @ 8mm

Priming required:Priming is required for porous or unstable surfaces – Use MC Primer Std for above freezing and MC Primer 0oC or below

Please consult the technical data sheet for full technical product data.

Preparation:

Thorough substrate preparation is essential.Concrete repairs should be prepared with squared off edges having a 4mm minimum vertical lip.Remove all loose material – wire brushing is advisable. Sweep clean or vacuum.The surface must be free from grease, oil or contamination.Ensure concrete is dry (moisture content not exceeding 5%) before priming.Caution – Cretex MC is methyl methacrylate based and has a characteristic odour during the vaporising of the solvent. Although non-toxic and non-injurious to health, this can cause tainting and OPEN food products should therefore be removed or sealed during and following application until the vapour has dispersed.

Priming:

The substrate should first be primed with Polycote MC Primer, brushing thoroughly into the entire surface. Once applied, sprinkle 0.5-0.9mm Calcined Bauxite or a suitable kiln-dried quartz aggregate onto the WET primer to provide a mechanical surface key for the material. Allow the primer to cure, normally within 40 minutes.

Mixing:

Using a clean plastic bucket of at least 25L capacity, add the resin to the powder and mix for 3 minutes using a heavy duty slow speed drill with a 0-15 litre mixing paddle until a homogenous mix is achieved.Ensure thorough mixing as an unmixed product will result in a poor or non-cure situation..Tip: For Cold Store Grade – the workable life of the material will be maximised if it has been stored at a very low temperature (e.g. in the cold store itself) prior to mixing

Application:

The material should be placed immediately after mixing. Trowel out to the required smoothness. DO NOT TAMP as this may cause the resin to rise to the surface leaving a weakened bond at the base of the repair material.Where the depth of repair requires more than one layer (see ‘Application Thickness’ on the front of this sheet) MC Primer should be applied between layers to aid inter-section bonding – see ‘Priming’.For vertical repairs – where step nosings or expansion joint edges have broken away, the vertical face of the repair material should be supported to prevent slumping. Suitable sized wooden shuttering should be covered with polythene to reduce adhesion, and should be removed as soon as the material is firm.Cretex MC may also be used for screeding and cove-forming – please contact Polycote Technical Helpline.

Technical Data Sheet

Technical Data Sheet