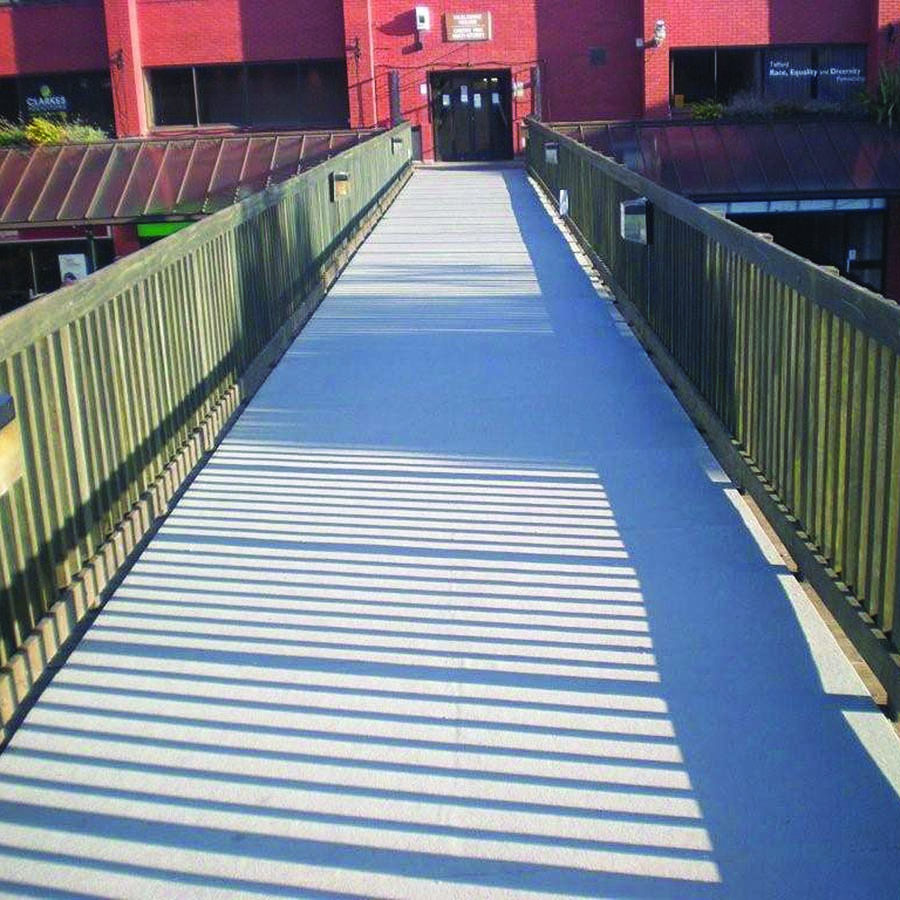

Cemcoat is a two stage product application. Each step is fast curing and the end result is a durable cementitious screed that can be used for many applications, whether it be the protection of old concrete from freeze/thaw issues to the coating of wooden sheeting for a temporary pathway across a building site. It is extremely strong and can withstand both heavy vehicular and heavy foot traffic.

Cemcoat is a polymer/cement based product designed to be applied over a wide range of surfaces to provide a durable surface strongly bonded to the substrate with a degree of flexibility to enable the accommodation of movement in the substrate and structure of the building.

Cemcoat can be applied to both horizontal and vertical surfaces and finished with a variety of textured and decorative effects.

Stage 1 – Squeegee and roller apply the Cemcoat Base – This an off-white, strong, polymer modified coating that provides the surface protection and help bind the concrete finish.

Stage 2 – Roller apply the Cemcoat Sealer – This is the final sealer that provides whatever colour you choose to further enhance the decorative and functional properties of the surface.

Use on:

Concrete, tarmac, wood, metal, plastic, galvanised metal, iron, fibreglass, asbestos, PU foam, etc

Use where:

Internal/External

Typical industries:

Used in all industrial, commercial and domestic areas. Heavily used in multi-story car parks, industrial yards and within the farming industry in areas such as grain stores, dairies, piggeries, abattoirs and silage clamps

Type of job:

Cemcoat is commonly used for adding slip resistance and smoothing out and protecting surfaces on loading and parking bays, ramps, wooden walkways, decking, driveways and footpaths. Cemcoat is excellent for vertical surfaces and decorative effects, columns, plinths, planters, etc. and can be easily over coated to further enhance the appearance and / or functional properties

Approximate coverage:

Cemcoat Base – 17.5 kg unit – 7.5-9 sq.m @ 1mm nominal thickness.

Cemcoat Sealer – 1.7 kg unit – 10 sq.m

Special features:

Heavy duty, impact resistant, flexible, will adhere to damp surfaces, prevents further erosion, can be used as part of a waterproofing system, use on vertical and horizontal surfaces

Cemcoat Base

Pot life:60 mins @ 20oC

Application temperature:5oC – 25oC

Cure time: Re-coat after 4 – 6 hours @ 20oC

Light wheeled traffic – 24 hours

Full traffic – 3 days

Depth of repair (1 layer):1mm nominal thickness. If a certain thickness or extra durability is required, Cemcoat can be built up by multiple applications. In any case, two coats are normally advised

Number of parts supplied:2

Priming required:No. Dampen porous surfaces prior to application

Cemcoat Sealer

Pot life:45 mins @ 20oC

Application temperature:5oC – 25oC

Cure time: Re-coat after 12 – 16 hours @ 20oC

Light wheeled traffic – 24 hours

Full traffic – 3 days

Number of parts supplied:2

Priming required:No.

Please request a copy of the technical data sheet for full technical product data. Please call us on 01234 846400 or email to uksales@devsite101.website.

Preparation:

Thorough substrate preparation is essential.

All surfaces must be clean and free from loose materials. Areas contaminated by oil and grease should be thoroughly cleaned with Polycote Degrease IT.

Defects in existing surfaces must be made good, before applications. Where evidence of organic growth, lichen, moss etc. is apparent, surfaces must be thoroughly cleaned and must be treated with a long term fungicidal/biocidal treatment such as Polycote Destroy IT. Careful attention should be given to areas in both horizontal and vertical surfaces such as cracks and joints where water penetration is possible. Rust etc must be removed and treated with a suitable metal primer such as Polycote ZP Primer.

Cemcoat Base:

Mixing:

The ideal mixing tool is a slow speed drill fitted with a multi action mixing paddle. Suitable mixing paddles can be purchased from Polycote.

The Cemcoat Base unit of material supplied is based on the standard mix of 5 litres of liquid to 12.5 kgs of powder (i.e. 1 part liquid to 2.5 parts of powder) but it should be noted the ratio of liquid to powder can be adjusted to suit individual applications in terms of surface, usage and prevailing temperature. The ratio can vary from 1 part of liquid to between 1.8 up to 3.75 parts of powder.

ALWAYS add the powder into the liquid – slowly, continually mixing until all the powder to be used is added. Continue mixing for a further 2 to 3 minutes ensuring there are no lumps in the mix. The final consistency should be similar to that of a thick cream.

Please note: Cemcoat Base is a balanced formulation and no additional water should be added to the mixture.

Application:

Before application of Cemcoat Base to horizontal or vertical surfaces, ensure that porous surfaces are damp, this can be done simply by spraying a hose over the area. The area must only be damp and no puddles should be present. Ensure any standing water is removed.

Please note: all warm surfaces are best cooled by dampening down with water before application of the Cemcoat Base. Should you wish to apply a further coat of Cemcoat, a very light spraying of water will again, aid the spread of the material.

CAUTION: Do not apply Cemcoat Base on hot surfaces or at times of very strong sunlight and high temperatures as this could accelerate the drying of mixed concrete and produce a very rapid cure of the applied material. Although very rare, this situation can subsequently cause hairline cracking.

Cemcoat Base is extremely simple to apply using either a brush, roller, trowel or squeegee.

From the mixing vessel pour out a quantity of material that can be easily and uniformly spread. When completing larger areas, we advise using our straight bladed squeegee, spreading the Cemcoat out evenly and to the desired thickness / coverage rate. Using a roller and whilst still wet (immediately) , roll out the Cemcoat to a uniform finish. Take care when rolling that each ‘roll’ is pulled in a neat straight line to achieve the final texture / slip resistance required. Repeat the mixing and application method until the selected area has been completed.

Over coating can be completed as soon as the first coat has dried (between 4 and 6 hours according to climate conditions).

Cemcoat Base should not be applied where the air or background temperature is likely to fall below 5oC or where there is a risk of rainfall on exposed applications prior to full curing being achieved.

Cemcoat Sealer:

Mixing:

The ideal mixing tool is a slow speed drill fitted with a multi action mixing paddle. Suitable mixing paddles can be purchased from Polycote.

The Cemcoat Sealer unit is made up of two pre-measured parts and we do not recommend splitting this down to make up smaller units.

Please note: Cemcoat Sealer is a balanced formulation and no additional water should be added to the mixture.

Application:

Before application of Cemcoat Sealer to horizontal or vertical surfaces, ensure the Cemcoat Base is fully cured and surface is clean, solid and dry.

Cemcoat Sealer is extremely simple to apply using either a brush and/or a roller.

From the mixing vessel pour out a quantity of material that can be easily and uniformly spread to the desired thickness / coverage rate.

The Cemcoat Sealer should not be applied where the air or background temperature is likely to fall below 5oC or where there is a risk of rainfall on exposed applications prior to full curing being achieved.

Safety Data Sheet

Safety Data Sheet