For your interest:

Acraflex RG has been truly tested on a large roof area in Spain alongside many other coatings such as bitumens, acrylics and polyurethanes.

Whereas all the other coatings have peeled, split, bubbled and cracked under such constant stress and high UV attack, Acraflex RG has proven beyond doubt its superior and outstanding qualities.

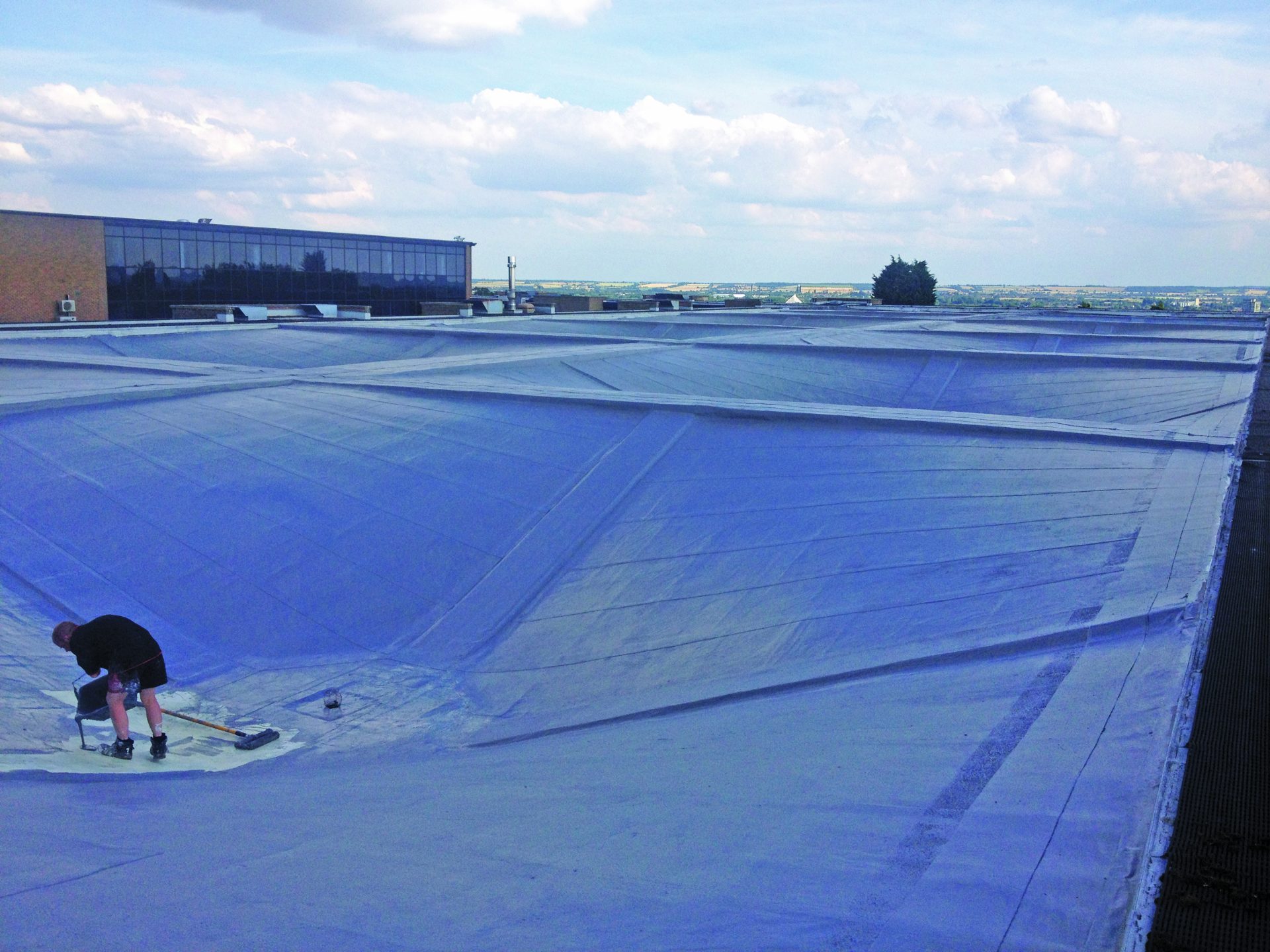

Acraflex RG (Rubber Grade) is our latest technological advancement in roof coatings and is extremely tough and long lasting with a high grade of rubber within the formulation.

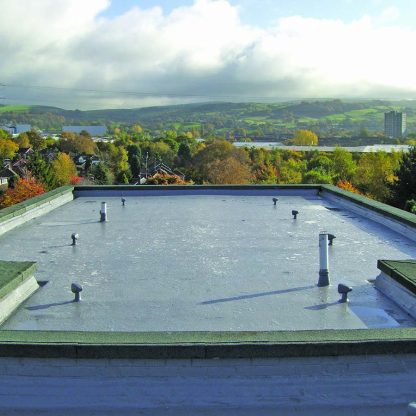

It is extremely flexible; highly elastic and capable of withstanding constant movement from the roof, and can also withstand pedestrian traffic. Acraflex RG is suitable for both flat and pitched roofs.

Acraflex RG will adhere to almost any wall or roof substrate and due to the rapid curing design, it will withstand rain immediately after application with no adverse effect.

Applied by brush or roller.

Number of parts:1

Application temperature:Between 2oC and 35oC, relative air humidity 85%

Curing time:8 hours (or overnight)

Coverage:5kg: 4 – 5m2

20kg: 16 – 20m2

Please consult the technical data sheet for full product technical data.

Preparation:

Thorough substrate preparation is essential.

All necessary repair work should be carried out prior to application of the coating and the prepared surface should be clean, sound and free of flaking or loose material, moss or fungal growth. Any water, oil or grease must be removed and the surface allowed to dry.

Due to the wide variation in roofing materials and conditions, the following are generalised recommendations only. Please contact the Polycote technical helpline if more specific guidance is required for your application.

Moss, lichen and fungal growth – remove by stiff broom or jet washing, then treat the area with Polycote Destroy IT to inhibit further growth – Please see the relevant data sheet.

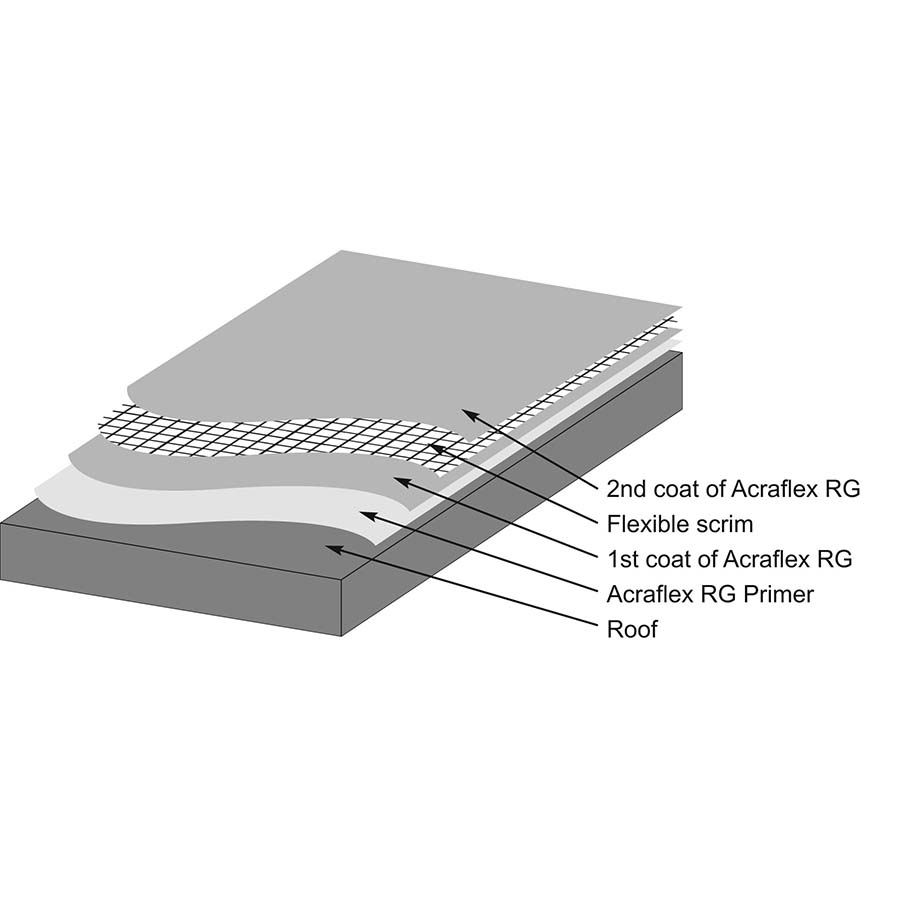

Porous surfaces – Acraflex Rubber Grade should be applied to porous surfaces which have been primed using ARG Primer.

Non-porous surfaces – Shiny surfaces should be abraded to allow for better adhesion. Acraflex Rubber Grade should be applied to non-porous surfaces once they have been thoroughly cleaned and are completely dry.

Asphalt, bitumen and felt roofs – New asphalt and bitumen surfaces should be allowed to weather prior to application.

Metal surfaces – remove all loose and flaking rust and treat with Polycote Rustex – refer to relevant Data Sheet. New galvanised steel should be allowed to weather, or may be treated with a suitable primer – Please see the relevant Data Sheet.

Gaps, cracks, joints and holes – Acraflex Rubber Grade will fill or bridge hairline cracks. Wider cracks or joints should be raked clean, opened out and filled using Polycote Rooflex Sealant. Allow sealant to cure before embedding membrane and overcoating – see under ‘Application’ following.

Application:

Having prepared and primed the surface, and making sure it is completely dry, apply a generous coat of Acraflex Rubber Grade by brush or roller.

Any filled cracks or joints that are subject to movement should be reinforced with Polycote Flexible Membrane.

The membrane should be cut to approximately 100mm wide strips of appropriate length and laid into the wet Acraflex Rubber Grade coating over the repair, stippling with a paintbrush to integrate the membrane into the wet coating.

After all necessary membranes are embedded, an overall coating may be applied by brush or roller.

One overall coat is normally sufficient. However, further coats may be applied if required, allowing drying intervals between coats.

Technical Data Sheet

Technical Data Sheet