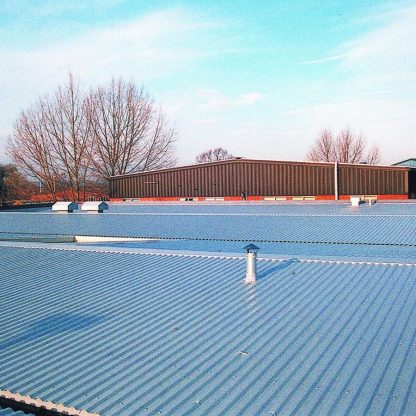

Typical Uses:

Suitable for both flat and pitched roofs. Superb adhesion to most surfaces: felt, asphalt, asbestos, metal, concrete, brickwork and slate.

Acraflex is a high quality solvent-based acrylic waterproofing compound incorporating high build fibres that interlace to reinforce the roof coating. Acraflex High Build provides a single-coat, durable long-term patch repair and waterproofing solution that is immediately waterproof and will withstand rainfall as soon as it is applied.

Single pack product – no mixing required

Number of parts:1

Application temperature:5oC to 25oC

Curing time:Up to 3 – 7 days

Coverage:5kg: 4 – 5m2

20kg: 16 – 20m2

Please consult the technical data sheet for full product technical data.

Preparation:

Thorough substrate preparation is essential.

All necessary repair work should be carried out prior to application of the coating and the prepared surface should be clean, sound and free of flaking or loose material, moss or fungal growth. Acraflex High Build must only be applied when the surface is dry.

Due to the wide variation in roofing materials and conditions, the following are generalised recommendations only. Please contact the Polycote technical helpline if more specific guidance is required for your application.

Porous/friable surfaces – concrete and asbestos cladding, sheeting and guttering should be primed using Acraflex™ Primer. These surfaces must be jet washed prior to applying the primer.

Non-Porous surfaces – polished bricks should be power washed, abraded and completely dry and free from any contamination before coating with Acraflex High Build.

Bitumen and felt roofs – discolouration may occur on new asphalt, tar or bitumen suraces, so an extra coat may be required for decorative purposes.

Metal surfaces – including ferrous: new, weathered and previously painted galvanised steel and iron and non-ferrous metals: aluminium sheeting and aluminium alloy box gutters. All these areas should be suitably prepared and primed (see relevant Data Sheet).

Previously painted or coated surfaces – we recommend that you carry out adhesion tests on any existing coating or substrate before applying Acraflex High Build.

Gaps, cracks, and joints – Acraflex High Build will fill or bridge hairline cracks. Wider cracks or joints should be raked clean, opened out and filled using Polycote Rooflex Sealant. Allow sealant to cure before embedding membrane and overcoating – see under ‘Application’ following.

Crazed areas – must be primed with Acraflex Primer before coating with Acraflex High Build.

In areas where excessive movement may occur, additional reinforcement with Polycote Flexible Membrane must be incorporated into the coating.

Important:

Acraflex High Build is not recommended for the treatment of wooden surfaces, tanking, fishponds or any internal use.

Air conditioning vents should be sealed for a minimum of 24 hours during and after the application.

Acraflex High Build should only be used on applications in the UK.

This coating is not suitable for heavy foot-traffic areas.

Minimum Finished Fall: when using Acraflex High Build it is important that a minimum finished fall of 1:80 is achieved, as stated in BS 6229.2003 (Code of Practice for the application of Liquid Applied Waterproofing Systems to flat roofs with continuously supported coverings).

Application:

Having prepared the surface, any filled cracks or joints that are subject to movement should be reinforced with Polycote Flexible Membrane.

Such repairs should then be coated with Acraflex, and the membrane should be cut to approximately 100mm wide strips of appropriate length and laid into the wet Acraflex over the repair, stippling with a paintbrush to integrate the membrane into the wet coating.

After all necessary membranes are embedded, an overall coating may be applied by brush or roller. If this is done immediately, care should be taken when overcoating the placed membranes to avoid disturbing them. If possible, allow overnight setting of the embedded membranes before overcoating the entire roof surface. One overall coat is normally sufficient.

Further coats may be applied if required, allowing drying intervals between coats.

On previously painted surfaces two thin coats rather than one thick coat should be applied as this will prolong the life and performance of the coating.

Technical Data Sheet

Technical Data Sheet