Stoneguard is a single pack, water dispersed fluoropolymer based coating which provides an invisible protective barrier.

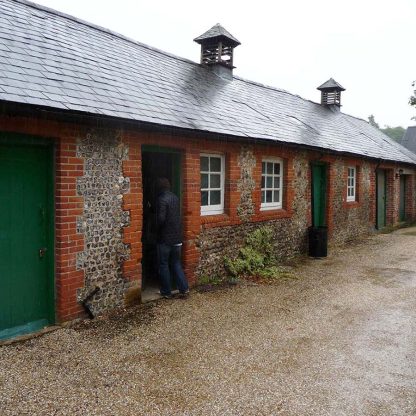

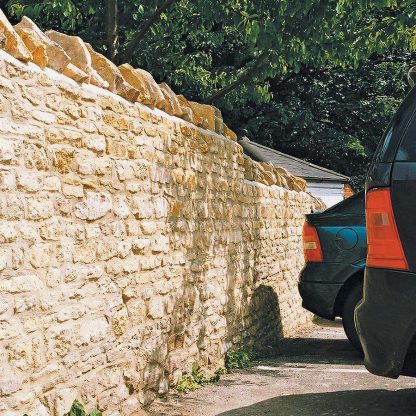

Use on:Brickwork, stone, concrete and other porous mineral surfaces

Use where: Internal/External

Type of job: Ideal for water-repellent treatment of brick and stone buildings – especially for listed buildings – and to give oil resistance to driveways, parking bays and paved areas, factory walls, aircraft hangars and other surfaces vulnerable to oil and liquid penetration, atmospheric pollutants and other contaminants

Approximate coverage: 5L 70 – 100m2 subject to porosity and conditions

Special features:Extremely durable and long lasting, prevents surface erosion caused by freeze-thaw cycles, retains breathability of construction materials, does not affect look or characteristics of treated surface

Application temperature:8oC – 40oC

Number of parts supplied:1

Cure time:Touch dry – 30 mins

Withstands rain within 3 hours

Full chemical cure – 24 hours

Priming required:No

Please consult the technical data sheet for full technical product data.

Preparation:

Remove all loose, friable or flaking material and any fungal or algae growth. Ensure the surface is clean, dry and free of oil or other contamination. Wash thoroughly with clean water and allow to dry. Any repair work should be complete before application of Stoneguard.

Application:

A single thorough coat is normally sufficient. Depending on the size and evenness of the surface to be treated, Stoneguard may be applied by brush, roller (if the area is very flat), mop or coarse spray. Always start from the bottom of the wall. Fine spray should not be used and precautions must be taken to prevent inhalation of airborne droplets. Any pooling should be brushed out. If using a spray, use a coarse spray and apply using HVLP equipment.

Ensure the surface is completely covered.

If the surface is very porous, a second coat may be required which must be applied after a minimum of 30 mins.

Tile grout sealing – apply Stoneguard over entire tiled area with a brush or roller, re-coating after 1 hour. Avoid contact with water for 24 hours, then remove residue from glazed tile surfaces with soap and water.

Technical Data Sheet

Technical Data Sheet