Typical Uses:

Ideal for both concrete & wooden surfaces. Typical applications include factory floors, warehouses, loading areas & workshops.

Flortex PU Clear is a self-priming single pack high solids polyurethane floor coating. Its tough clear gloss finish is easy to maintain and provides a seamless oil and chemical resistant barrier, capable of withstanding forklift traffic and hot tyres.

Coverage: 5-8 sq.m./litre

Application temperature:5oC – 25oC

Initial cure time:2-3 hours @ 20oC

To accept traffic:3-4 hours depending on temperature & humidity

Overcoat (if required) time:idealy 12-18 hours, but within 48 hours

Full strength cure time:7 days

Number of parts supplied:1

Coverage:25-40 sq.m. per 5l unit

100-160 sq.m. per 20l unit

Primer required:No

Storage temperature:10oC – 25oC

Please consult the technical data sheet for full technical product data.

Preparation:

Thorough substrate preparation is essential.

Recommended methods are:

Powerfloated concrete – use a Vacuum Assisted Shotblaster to remove weak laitence and provide a surface key for the coating. If this is not possible, chemically etch with Polycote Etch IT then rinse thoroughly and allow to dry.

Loose paint or rust – remove, using a Vacuum Assisted Shotblaster, Floor Grinder or equivalent method.

Loose or friable concrete – use a Vacuum Assisted Shotblaster. If this is not possible, chemically clean with Polycote Etch IT then rinse thoroughly and allow to dry.

Oil or grease – use Hot Compressed Air for large areas of contamination. Smaller, isolated deposits may be chemically cleaned with Polycote Degrease IT, then rinsed thoroughly and allowed to dry.

Timber – remove any loose paint and abrade thoroughly. Ensure surface is clean and free of dust, oil and grease.

See relevant Data Sheet prior to application.

Once prepared, the area must be kept clean and free of traffic.

IMPORTANT NOTE

Flortex PU Clear should not be applied to surfaces with a moisture content exceeding 4%.

Application:

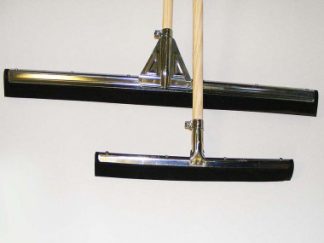

Flortex PU is applied by brush or roller (Please note; a nylon, medium pile roller sleeve is best).

The most important consideration now is the porosity of the substrate, how much you would like the coating to penetrate and what sort of finish you would like.

The advice given for very porous surfaces is to ‘flood’ the floor so that good penetration is achieved as this will greatly strengthen the substrate. However, take care not to leave any standing coating to ‘puddle’ as the product may ‘foam’ and leave a milky white discolouration.

It is then important to note that the floor may then also look patchy, this being caused by some areas being fully coated (due to less porosity) and appearing glossy, whilst other more porous areas are left matt. This is simply where the coating has penetrated and disappeared from the surface. Give further coats until a uniform finish is achieved. Two coats will suffice for nearly all floors, although please note that very porous surfaces might take even three or four coats. Remember; the greater the porosity, the less coverage you will achieve.

Make certain that sufficient time is allowed between coats to allow the previous coating to fully cure, this normally being from 2-4 hours depending on humidity and temperature. If the interval between coats exceeds 48 hours, it is advisable to abrade the surface to ensure good intercoat adhesion. If the second coat is applied before the first coat has dried, this can dramatically affect the ultimate curing time and the adhesive strength of the material, once cured.

Technical Data Sheet

Technical Data Sheet