Easiflow RS Grout is a Portland cement based product , with good flow and non-shrink properties, designed for high early strength gain and rapid return to use.

Use on: Concrete, metal, brick, stonework and rock

Use where: Internal/External

Typical industries: Construction

Type of job: Designed for base plates, crane rails, bridge bearings, cable ducts, stanchion bases, ground anchors, etc.

Approximate coverage: 25 kg unit – 12L Yield

Cure time: 6 hours @ 20oC

Special features: High flow, non-shrink formulation, good vibration resistance, high strength, chloride free – can be used in contact with steel.

Pot life:15 mins @ 20oC

Application temperature:5oC to 45oC

Depth of repair (1 layer):10mm – 100mm

Fully cured strength:1 hour 12N/mm2

1 day 40N/mm2

28 days 70N/mm2

Number of parts supplied:1

Priming required:No

Preparation:

Thorough substrate preparation is essential.

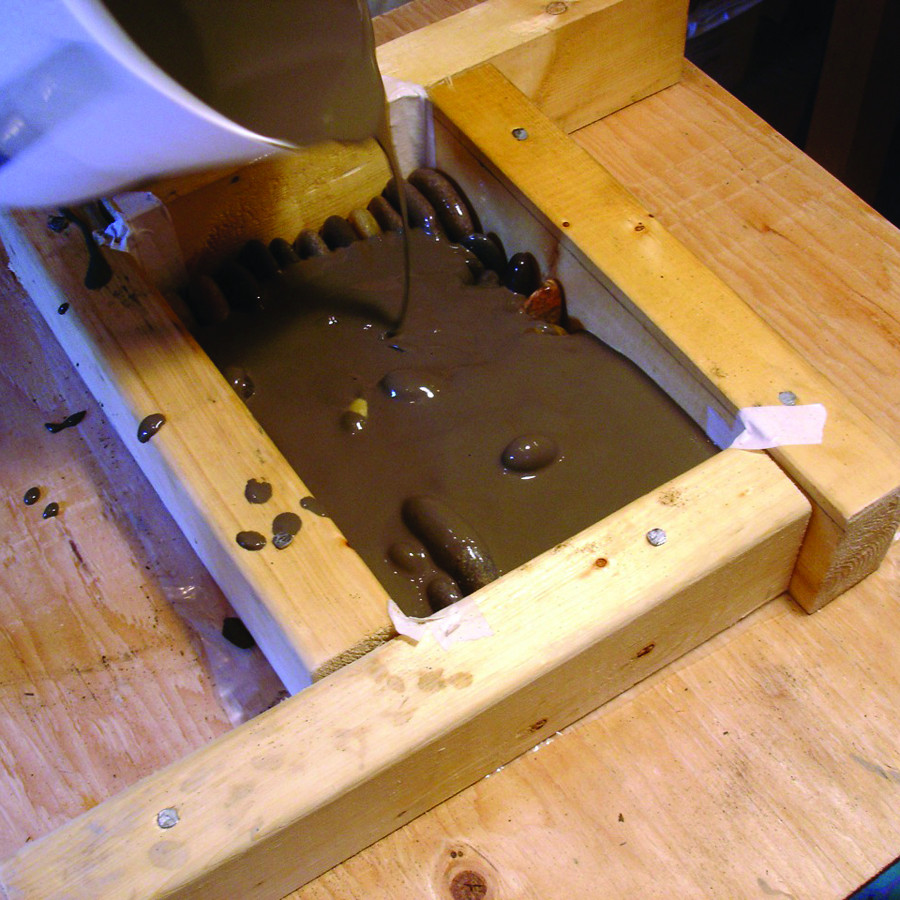

Formwork should be erected and made grout-tight.

The formwork must be designed with sufficient hydrostatic head to ensure grout flows into and across the grouting area.

Ensure that all surfaces with which the grout will come into contact are clean and dust free.

A strong concrete substrate free of all friable material will enhance a good bond.

Concrete surfaces must be thoroughly soaked with water and all standing water, prior to application, must be removed.

Mixing:

For each 25kg bag of Polycote Easiflow RS Grout, 3L to 3.75L of water is required.

Single bag mixes should be prepared using a high torque slow speed mixing paddle. Pour the required quantity of clean water into the mixing vessel.

Slowly add Polycote Easiflow RS Grout to the water whilst continually mixing. Continue mixing for 1 minute then place grout immediately.

Application:

Polycote Easiflow RS Grout should be hand poured into place immediately after mixing.

Continuous application is important, pouring from one side of the formwork until the grout appears at the opposite side of the grouting area.

Do not disturb untill the grout has hardened.Polycote Easiflow RS Grout may be applied at temperatures between 5oC and 35oC.

For temperatures above 20oC care should be taken to avoid premature setting before complete application has been achieved.

Safety Data Sheet

Safety Data Sheet